Watch Data

Watch no. 62

|

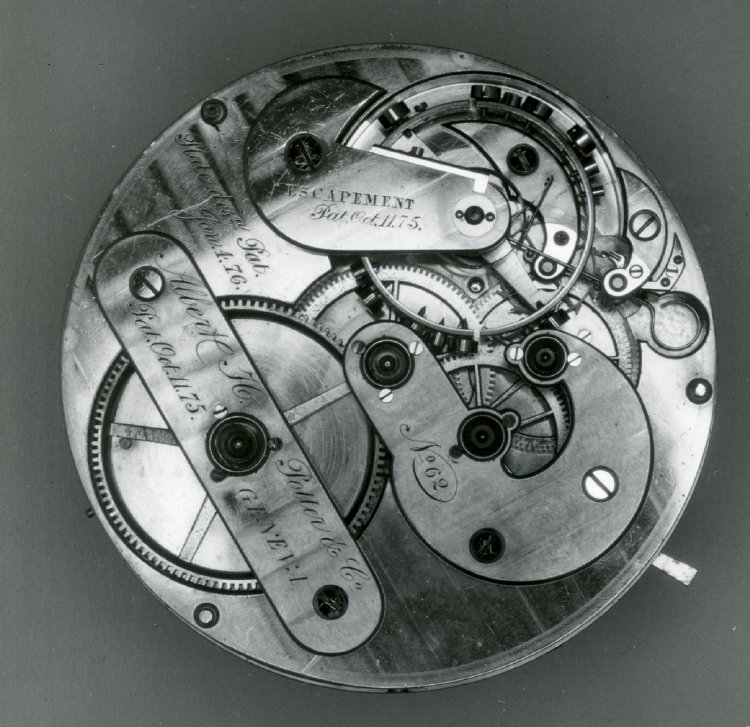

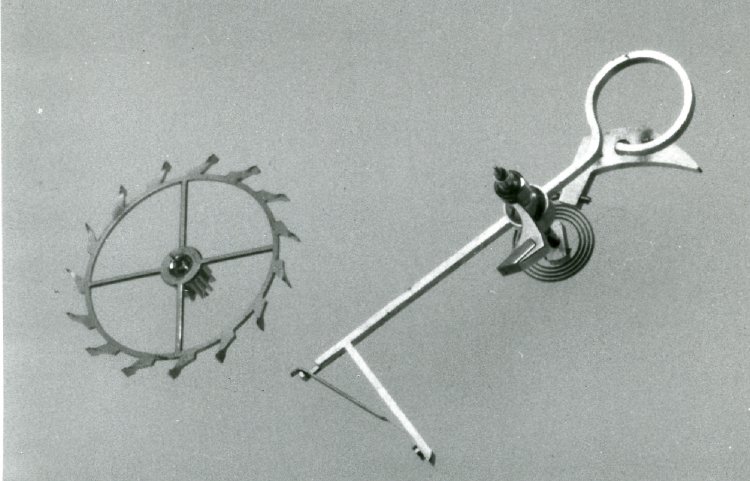

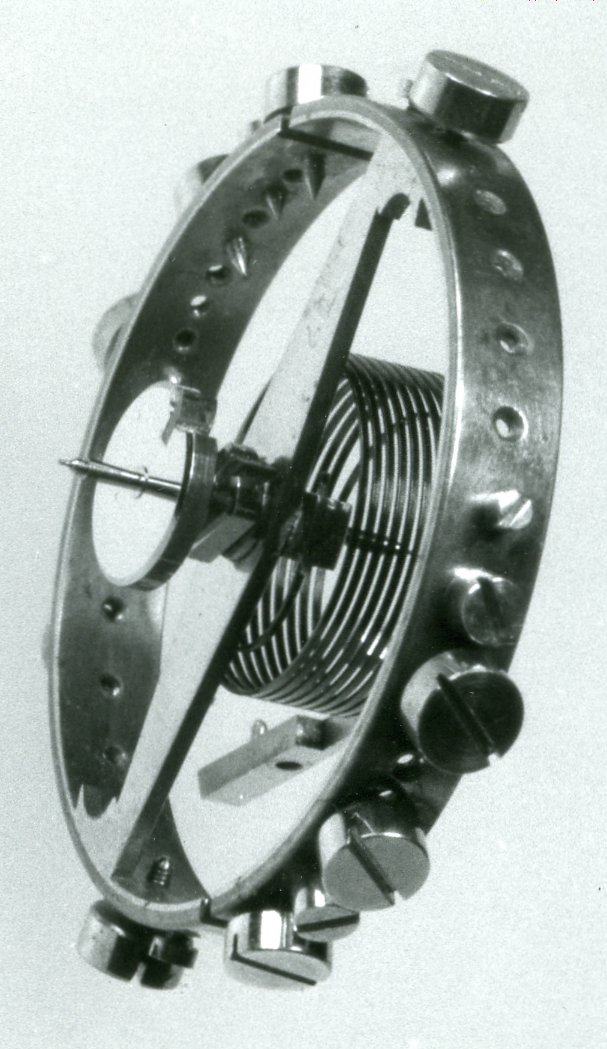

Case: Unknown, now replacement brass case

Dial: Movement: Provenance: 18?? - Potter, Geneve 1??? - Malcolm Gardner 1932 - Courtenay Adrian Ilbert 1958 - British Museum, " Description BRASS-CASED SUBSIDIARY SECONDS POCKET-CHRONOMETER WITH PIVOTED DETENT ESCAPEMENT. Chronometer watch. Pivoted detent escapement. Enamel dial. Later brass case. Inscriptions Inscription Type: signature Inscription Content: Albert H. Potter & Co., Geneva, Pat.Oct 11.75. Dimensions Diameter: 56.6 millimetres (case) Diameter: 50.8 millimetres (dial) Thickness: 19.7 millimetres Condition -2-1995/OCT Curator's comments Comment from Anthony G. Randall and Richard Good, Catalogue of Watches in the British Museum. Vol. VI (1990) Made by Albert H. Potter, c. 1900 Chronometer Signature: On the barrel bridge 'Albert H. Potter & Co. GENEVA Pat. Oct 11.75'. On the balance cock 'ESCAPEMENT Pat. Oct. 11.75.' On the back plate 'Plate des, 2. Pat. Jan 4.76'. On the centre, third and fourth cock 'No. 62'. Case: Later brass case with glazed front and back bezels. Diam. 56.7 mm, th. over glasses 19.1 mm Dial and hands: Flat enamel canister dial with sunk subsidiary seconds, and with a positioning peg in the edge of the plate, and a corresponding slot in the nickel ring. On the dial 'Albert H. Potter & Co.' Geneva. Blued steel hands. See Jules Jurgensen registration no. 1958,1201.1728 for a similar dial and hands. Movement: Front plate diam. 46.7 and 45.7 mm; front plate th. 7.0 mm; frame h. 8.7 mm. Frame: A massive disc of nickel brass is deeply hollowed to accommodate the barrel, going train, escapement and balance, top bearings being provided in bridges and cocks. Recesses are also turned on the dial side of the plate for the keyless work, motion work and a detachable plate with the third, fourth and escapement arbor lower bearings. The movement was secured in its case by three screws from under the dial. Each screw passes right through the plate and has a positioning pivot on the other end, presumably to fit into a corresponding hole in the case middle. The central portion of each screw is a boss with a peg set in it, the plate being hollowed to receive them. On turning the screw the peg swings out to contact a fixing block on the inside of the middle of the case. Going barrel and keyless work: English type of rocking-bar keyless work, hand set operated by a lever. The barrel ratchet wheel with Geneva stop-work and with integral hollow barrel arbor actually pivoting in a hole of large diameter in the main plate. This wheel kept in its recess by three 'tags' which overlap it and are screwed to the plate. The brass great wheel screwed to a collet on an arbor pivoted in jewels in a bridge on the back of the main plate and in the barrel ratchet wheel. The finger of the stop-work carried on a square on the end of the great wheel arbor. The barrel free to turn on the great wheel arbor, its open end towards the main plate. A peg in the closed end of the barrel passes between the spokes of the great wheel and supplies torque by pressing against a spoke. The centre wheel is protected from the open end of the barrel facing towards it, by a disc concentric with the barrel, passing over the centre wheel and secured to the main plate by two screws. On turning the barrel ratchet wheel in the direction of wind, the inner end of the mainspring is carried round as the spring is wound. The barrel, in trying to turn, applies pressure to the great wheel. Since the stop-work is between the great wheel arbor and the barrel ratchet wheel, winding causes the stop-work to turn in one direction, and the rotation of the great wheel arbor causes it to turn in the other. The purpose of this apparently complicated and elaborate system is to provide a measure of safety for the going-train in the event of breakage of the mainspring. If the mainspring breaks at or near its inner end when wound, it will fly round inside the barrel until tight against the barrel wall to which it will transfer its momentum. The barrel will turn violently backwards and presumably the peg will be sheared off against a spoke of the great wheel. The system, in an improved state, was later used by the Waltham Watch Company. Its disadvantage in this example is that the going-train is not completely protected, and the extra height needed to lodge all the parts is considerable. There is evidence that some other coupling between great wheel and barrel existed, a sink and a screw hole remain in the barrel wall, and a steel pin which has sheared off. Another advantage is that the great wheel with only one pivot on the end of the arbor where it is mounted stands more chance of being true. Also, the pivots are of a much smaller diameter, thus reducing frictional losses. Going train: Conventional train with very high numbered pinions, the brass wheels electro-gilded to a whitish finish. The leaves and ends of the pinions left smooth but not polished. The undercuts carefully turned, the arbors dull polished, the pivots and shoulders probably once highly polished. Only the escape pinion has highly polished leaves and ends. Jewelling: All the pivots of the going train and escapement arbors run in pierced jewels, those of the escapement with endstones. Only the centre arbor lower jewel bombé, the other train jewel faces flat against the pivot shoulders. Escapement: A form of pivoted detent escapement. The steel escape wheel with polished leading edges and tops of the teeth, sunk out on both sides leaving only the ends of the teeth standing to the full thickness. The detent with locking pallet on a separate short arm, a spiral return spring of 4½ turns with a steel stud and collet. The gold passing spring screwed to the end of an arm integral with the main body of the detent, but standing at right angles to it. The action of the gold passing spring is most unusual. The end of the detent has a slot cut in it, leaving a portion like a pin standing on end. The end of the passing spring is bent around this so that it points towards the balance. The action of unlocking occurs when the passing spring end is pressed towards the peg, causing the detent to move. During the passing action the spring flexes slightly and the end moves away from the peg and into the slot. The radius to the tip of the discharge roller jewel is much greater than usual, being nearly the same as that of the impulse roller. The steel impulse roller is polished all over and set with a ruby pallet with radial impulse face. The jewelled discharge roller, also of polished steel, with two flats for setting, is mounted between the impulse roller and the balance. Balance: Possibly a Guillaume bimetallic balance of nickel steel and brass, with steel quarter screws and gold compensation screws. The bimetallic rims unusually high. Diam. of rim 16.8 mm, h. 2.44 mm. Balance spring: Blued steel helical spring of 11 turns with terminal curves, free sprung to a steel stud on the edge of the balance cock and a bar shaped polished steel collet. Going-train counts: Great wheel 108 teeth, 5 arms Centre pinion 18 leaves, wheel 104 teeth, 5 arms Third pinion 13 leaves, wheel 90 teeth, 5 arms Fourth pinion 12 leaves, wheel 100 teeth, 5 arms Escape pinion 10 leaves, wheel 15 teeth, 4 arms Beats per hour: 18,000 Motion work: Cannon pinion 12 leaves, minute pinion 10 leaves Hour wheel 40 teeth, minute wheel 36 teeth. Keyless work: Pendant bevel wheel 24 teeth Central rocking-bar wheel 42 teeth Intermediate winding wheel 34 teeth Intermediate hand-set wheel 23 teeth Second intermediate hand-set wheel 19 teeth Barrel ratchet wheel 72 teeth Provenance: Ilbert Collection; purchased by Ilbert from Mal¬colm Gardner in 1932. Note: An English patent, No. 2985, was taken out in 1875 by a patent agent, W. R. Lake, on behalf of Albert Henry Potter of Chicago, Illinois, USA. Among the inventions included for protection are: a) An exceptionally thick watch movement front plate to provide greater rigidity and more effective dust exclusion. b) A continuous auxiliary compensation balance somewhat similar to one of Dent's. c) A safety mainspring barrel to protect the watch in the event of mainspring breakage. d) A pivoted detent escapement designed to reduce the angle through which the balance must move in order to unlock the escapement, thus reducing the risk of 'setting' or stopping in wear. With the exception of the balance, all these inventions are included in this watch. Bibliography: 'The American Horologist', September 1941, p. 36. Acquisition date 1958 Acquisition name Previous owner/ex-collection Courtenay Adrian Ilbert (biographical details | all objects) Acquisition notes Following the successful acquisition of the celebrated Ilbert collection of clocks (1958,1006 collection), prints and other related materials made possible by the generous donation of funds by Gilbert Edgar CBE Ilbert's watches were then acquired using funds provided by Gilbert Edgar, public donations and government funds. " |

|